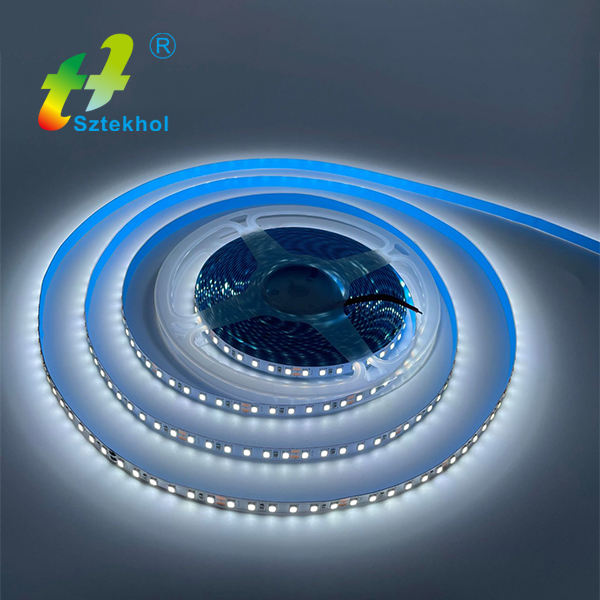

As an innovative product of modern lighting technology, flexible LED light strips have shown unique advantages in commercial space, home decoration, automotive lighting and industrial signs with their ultra-thin structure, high flexibility, energy-saving characteristics and intelligent control. The following analysis is carried out from three aspects: technical characteristics, application scenarios and development trends:

1. Technical characteristics: breaking through the core advantages of traditional lighting

Flexibility and plasticity

Using FPC (flexible circuit board) as the substrate, the light strip is only 0.1 cm thick and can be bent to an arc of 8 cm in diameter, supporting any shape in three-dimensional space.

Precise cutting design (each 3 LEDs are a group), suitable for irregular installation environments, such as curved ceilings, curved signs, etc.

Efficient energy saving and long life

The power consumption is only 1/5 of that of traditional neon lights (such as 4.7W/m vs 26.25W/m), the life span exceeds 100,000 hours, and the maintenance cost is significantly reduced.

Low voltage (24V DC) operation, combined with shockproof and temperature resistance, is safer than high-voltage glass neon lights.

Lighting effect and color control

High-brightness LED chips (80-90 pieces/m) achieve uniform light emission, support RGB full-color and dynamic dimming, and meet scene-based lighting needs.

With the intelligent controller, dynamic effects such as gradient, jump, and flowing water can be achieved to enhance spatial interactivity.

II. Application scenarios: practical cases of multi-field empowerment

Commercial space decoration

Case: The hotel lobby and shopping mall windows are outlined by flexible light strips, combined with the intelligent dimming system to create an atmosphere and enhance brand recognition.

Advantages: No need for complex wiring, installation efficiency is increased by more than 50%, and later maintenance costs are reduced by 70%.

Home intelligent upgrade

Case: Embedded ceiling light strips, stair step lighting, color temperature and brightness are controlled by mobile phone APP, suitable for reading, gathering and other scenes.

Advantages: 3M double-sided adhesive fixation, convenient construction, compatible with smart home system, and realize the “no main light” design trend.

Automobile and industrial lighting

Case: Car interior atmosphere lights and industrial equipment identification light strips must meet IP68 waterproof, salt spray resistance and other harsh environmental requirements.

Advantages: Silicone sleeve + glue dripping process improves the protection level and extends the service life to 3 times that of traditional lamps.

3. Development trend: technology iteration and market expansion

Packaging technology upgrade

COB/CSP packaging: reduce LED spacing, improve light efficiency uniformity, eliminate “hot spot” problems, and adapt to high-end lighting needs.

Miniaturization design: CSP light strip thickness is further compressed, bending stress points are smaller, and meet the lighting needs of precision equipment.

Intelligence and integration

Internet of Things (IoT) fusion: The light strip has built-in sensors to achieve adaptive adjustment of ambient light, or linkage with security systems.

Modular design: supports rapid splicing and expansion, reduces the difficulty of large-scale project construction, and improves delivery efficiency.

Green and sustainable development

Environmentally friendly materials: use recyclable FPC and lead-free solder to reduce the environmental impact of production and waste.

Energy efficiency standards: meet the EU ERP energy efficiency certification and help achieve global carbon neutrality goals.

4. Purchase suggestions: key parameters and pitfall avoidance guide

Core parameters

Brightness and color temperature: choose according to the scene (such as 2700K-3000K warm white light for home, 4000K-6000K pure white light for commercial space).

Protection level: IP65 or above for outdoor use, IP68 for underwater scenes.

Cut length: confirm the minimum cut unit of each section (such as 3 LEDs) to avoid waste.

Quality identification

Appearance inspection: smooth surface without impurities, soft and full rubber, and correct cut mark.

Circuit test: observe the brightness uniformity after power on, no flicker or dark area.

Brand guarantee: choose manufacturers that have passed UL and CE certification and provide more than 3 years of warranty.

Conclusion: Future prospects of flexible LED light strips

With the iteration of technology and the upgrading of market demand, flexible LED light strips are transforming from “functional lighting” to “intelligent light environment”. In the future, its application potential in emerging fields such as metaverse display and biomedical lighting will be further released, becoming a key carrier connecting physical space and digital experience. For users, choosing a brand with technical strength and service capabilities will be the key to achieving efficient, safe and sustainable lighting.